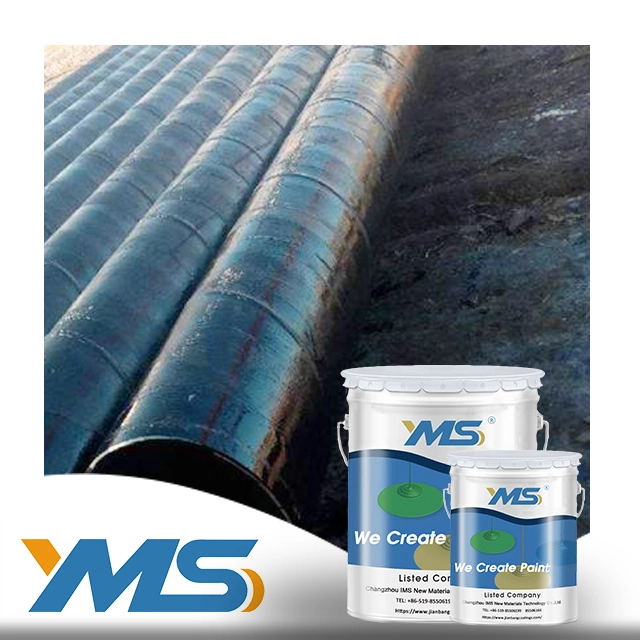

Professional Epoxy Coal Tar Pitch Thick Paste Coating anti corrosive paint factory for Winter

PRODUCT DESCRIPTION

This product is based on epoxy resin and coal tar pitch, added with ultra-fine pigment, filler and new additive. This product contains two parts: part A is the main paint and part B is the curing agent, among which the part B can be used for both primer and finish. This two-component epoxy coating can be cured at low temperature with construction temperature ranging from -10℃ to 36℃. The paint’s firm film is resistant to abrasion, sea water, and crude oil.

Typical Uses:

This product is able to provide long-term protection to steel in severe corrosive environment such as the bottom of ships and boats, crude oil tanks, ballast tanks and the outer wall of various buried steel pipelines in the cold areas.

PRODUCT SELLING POINT

● Nanotechnology, compact structure.

● Salt spray corrosion resistance ≥3000h,Resistance to aging≥5000h.

● 98% concentrated sulfuric acid for 1200h.

● Resistance to 30% hydrochloric acid for 1200h.

●Factory direct sale.

PRODUCT ADVANTAGES

PRODUCT APPLICATION GUIDE

| Mixing | Use the power mixer to mix the main paint evenly, and then as you stir it, you add the hardener until you get to mix well. |

| Thinner | Epoxy Paint Thinner |

| Mixing ratio | Part A: Part B= 20:5 (by weight |

Airless spray | Nozzle tip: 0.021~0.025inches Spray pressure: 15~18Mpa Thinner ratio:0~15% (by weight of paint) |

Brush, Roller | Recommended Must achieve required thickness. |

DRYING SCHEDULE

| Substrate Temperature | 10 ℃ | 20 ℃ | 30 ℃ |

To touch(150um) | 4h | 2h | 1h |

To handle(150um) | 24h | 12h | 6h |

| Min. recoating time | 16h | 8h | 4h |

| Max. recoating time | 10d | 7d | 5d |

| Pot life | 6h | 4h | 2h |

* Make sure no chalking and other contaminations before recoating.

* Above data for reference only, actual drying time and recoating time is dependent on temperature, dry film thickness, ventilation conditions.

PRODUCT SPECIFICATIONS

Color | Black |

Gloss | Semi-glossy |

Density | ~1.42Kg/L |

| Hardener | Epoxy curing paint |

| Solid Volume | (99±1)% |

Standard Film thickness | 150µm dry film thickness (about 230µm wet film thickness) |

Theoretical spreading rate | 3.58m²/Kg (200um dry film thickness) |

Full cure | (23℃±2 )7d |

| Flash point | 27℃ |

| Heat resistance | 120℃ |

TEST REPORT

Certificate

CUSTOMER EVALUATION

SHOW CASE

- 01

Dong Ying Olympics Sports Center

Products: Epoxy Sealing Agent + Epoxy Slurry Intermediate Layer+ Epoxy Self-leveling Floor Finish

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

- 02

PT.Conch North Sulawesi Cement

Products: Epoxy Sealing Agent + Epoxy Slurry Intermediate Layer+ Epoxy Self-leveling Floor Finish

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

03

PT Sgmw Motors Indonesia-lingyun Workshop

Product: Self-leveling Epoxy Floor Paint